Here in Montana, a lot of knife owners do a little fishing and a lot of hunting. For that reason, we took a slightly different approach to the design of our new fillet knife — and we're excited to share it with you.

We've seen a lot of demand for a knife that can break down meat but also fillet a marlin off the coast. Our existing knives work for the smaller catches a lot of fly fishers need them for, but bigger fish — whether in Montana or in coastal waters — need a bigger fillet knife.

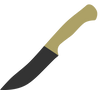

We designed the MKC Flathead Fillet Knife to be a well-rounded fillet AND boning knife that owners can use from the salmon-rich rivers of Alaska to the elk-laden butcher tables of Montana.

What Makes the MKC Flathead Fillet Knife Unique?

The MKC Flathead Fillet Knife has both the flexibility needed for filleting lots of fish and the rigidity and strong point needed for breaking down meat. A commercial fisherman filleting thousands of fish each day may want something with more flexibility in the blade, but this knife is designed for the hunter-angler who wants one knife they can take to the water or to the field.

Below are some characteristics that make this knife ideal for hunters who take those periodic big fishing trips, but need a knife that can bone out deer or elk the rest of the year.

AEB-L Stainless Steel

The first consideration for a blade that's going to be used in a saltwater application is rust. To combat this, we made the Flathead Fillet Knife with AEB-L stainless steel, which has a very high corrosion resistance. It also holds a good edge and is tough but flexible enough to make an excellent fillet knife.

For double protection, the Flathead also has a baked-on Cerakote finish, which is incredibly durable and damage-resistant.

G-10 Handles for Wet Conditions

Next, we needed a handle that would work well in both hunting and fishing situations. The G-10 material we already use for most of our knife scales fits the bill perfectly.

Impervious G-10 handles won't absorb salt water or rust. Even the titanium screws we use to attach the scales to the blade are corrosion-resistant. And because we know things can get slippery out on the water, we left some of the machining texture on the handle to improve grip in wet conditions.

We really considered the environments in which fishermen will be using the Flathead Fillet Knife. A lot of times, they're dealing with frigid water and freezing air, and they're wearing heavy rubber gloves to deal with fish. They need a knife they can really grip through those gloves.

It's the same for hunters in meat processing. They're often dealing with meat straight from a cooler and wearing Kevlar gloves to keep from getting cut. The tough, textured handle provides enough substance for them to hang on to in any situation.

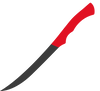

Thin Blade and Sharp Edge

The Flathead Fillet Knife is incredibly sharp, with a good point, an upswept tip, and a fair amount of edge to the cutting surface.

The blade tapers from the front of the handle all the way to the point, adding flexibility. The thickest part of the blade is .095", and the edge is quite thin at .012" to .015". We sharpen the edge at a 15-degree angle. The benefit of such a thin edge is that it's easy to resharpen, and it passes through whatever meat you're working on with ease.

It's so sharp, in fact, it almost needs a word of caution.

Just last week I was out with an avid salmon fisherman who spends 300 days of his year on the water. Using this knife, he sliced through the gills of a fish so fast that he ended up cutting himself pretty badly. He said he'd never in his life held a knife this sharp.

Working Knives for Working People

A lot of our customers are like me — last weekend I went salmon fishing, and in the fall I'm hunting elk and deer. That's why I think the Flathead Fillet Knife is the perfect addition to the MKC lineup. It fills a gap in our lineup for the fisherman-hunter who wants one knife that can do it all.

by Josh Smith, Master Bladesmith and Founder of Montana Knife Company