working knives for working people

MKC - 4 C's

Country: Supporting American manufacturing and jobs.

Customer: Building tools working people can depend on.

Community: Creating opportunities in our hometown.

Conservation: Protecting the outdoor spaces we all enjoy.

Our mission is to embody the best in American craftsmanship, the American worker & the American dream. For 30 years, Master Bladesmith Josh Smith has dedicated his life to delivering the highest quality knives. We dedicate ourselves to a lifelong relationship with our customers to ensure our knives will be passed down for generations. We are committed to giving back to our veterans, communities & the conservation of wild game, its habitat & hunting access.

Montana Knife Company

Quality American manufacturing isn’t just possible — it’s happening right here in Montana. We build premium knives working people can afford, proving that domestic production is both viable and valuable.

A Legacy of Craftsmanship

Montana Knife Company’s foundation began in Lincoln, Montana, where Master Bladesmith Josh Smith learned to make knives at age 11 under the guidance of his little league baseball coach, Rick Dunkerley. That early mentorship ignited a passion that led Josh to become the youngest Master Bladesmith in the world at age 19.

MKC MANUFACTURING BREAKDOWN

Knives Made For America

President, Founder & Master Bladesmith

Josh Smith

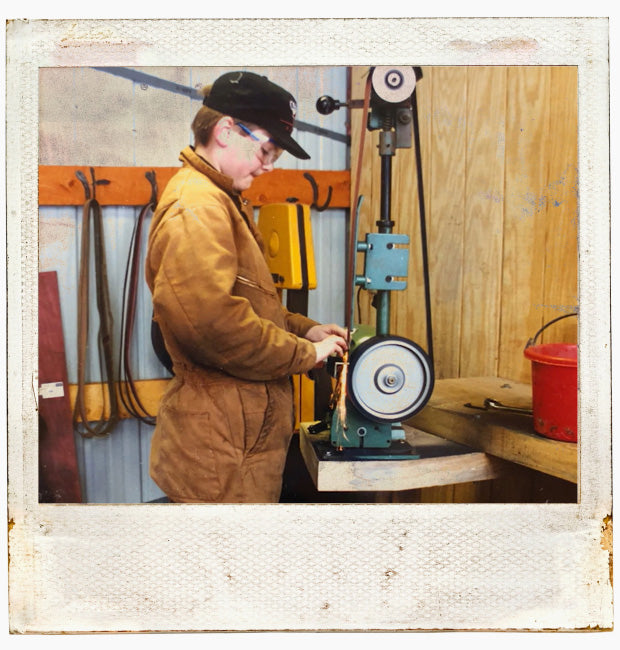

Josh grew up in Lincoln, Montana on the edge of the Bob Marshall Wilderness. At the age of 11 Josh’s baseball coach, Rick Dunkerley, began teaching him how to make knives. In the very beginning, Josh would go to Rick’s shop where he learned to remove stock blades under the guidance of Rick.

JOSH SMITH & KNIFE MAKING

Discovering Knife Making

I started making knives when I was 11 years old in the little town of Lincoln, Montana.

For Christmas that year, my parents bought me a blade by Rick Dunkerley, my little league baseball coach and an excellent bladesmith. Not long after that, Rick gave in to me bugging him and invited me up to his shop to teach me how to make knives.

After helping me with my first couple of blades, Rick told me that if I was serious about making knives, I needed my own shop. Even at age 11, I remember thinking I had found something I wanted to do for the rest of my life, so I was absolutely serious. I couldn’t get enough of it.

By saving money from mowing lawns and working for my parents, I was able to buy my first knife grinder and set it up in a corner of my dad's shop. That first grinder gave me the independence to start making knives entirely on my own.

After I made a mess of his shop, my dad decided it was time for me to have my own space. He enclosed a lean-to and set me up with a workbench and anvil. He even made everything full-sized to keep it functional as I grew, though that meant adopting a milk crate as a step stool for several years. My parents were always incredibly supportive of my knife making, something I appreciate even more now looking back.

I spent countless hours in that little shed, working before and after school and getting increasingly serious about my craft. My school science fair project even covered heat treating steel, which gave me the opportunity to sell my very first knives. I’ll never forget that my first customers were two of my teachers, who bought blades for $20 each.

Mastering the Art of Knife Making

At Rick's encouragement, I joined the American Bladesmith Society at age 12. After three years as an apprentice, I decided to create a set of blades to take the journeyman bladesmith test in Atlanta, Georgia. The test (which I’ll explain more in an upcoming article) was rigorous: A single knife had to chop through a one-inch rope, shave hair, and bend 90 degrees without breaking.

You can imagine how elated I was when I passed the test and became the youngest journeyman knife maker in the world. It was a huge accomplishment for me, proving to myself and others that I could make knives at a professional level alongside people three to five times my age and despite not even having a driver’s license yet.

I continued to learn and practice as much as I could, and would have loved to take the Master Smith test as soon as the minimum two-year journeyman period ended. But being a teenager with school, work, and sports took a front seat until my second semester at Montana State University. I spent that semester preparing, and at age 19, I traveled to Atlanta to take the second and final of the two ABS tests.

For this test, the blades I forged had to cut one-inch rope, chop through a 2x4, shave hair, and bend 90 degrees. A panel of Master Smiths again judged five other knives for craftsmanship and quality. It was an intense test, but I passed and became the youngest Master Smith in the world. I’ll never forget what an honor it was to be recognized on a national level for doing something I loved. I didn’t realize it then, but I’d only just begun.

The Dream of Knife-Making

My dream was always to start my own knife-making company. Knowing that, my mom even registered the name Montana Knife Companywith the state for me. College didn’t seem like the right path to take me where I wanted to go, so instead I worked in excavation and construction for several years, got married, and moved to Frenchtown, Montana, where I still live today. In Frenchtown, I became a full-time custom knife maker.

Making custom knives one at a time to support a family which grew to include four children was challenging and unpredictable, especially before I could sell my work online. With the crash of 2008, I wasn’t sure about the future of high-end custom knife making, so I ended up taking a job as a lineman.

Despite my long-held dream, the timing never seemed quite right to start Montana Knife Company. I didn’t feel ready personally or financially, and a divorce left me caring for four children as a single dad. There wasn’t much time for knife making. I just had to do what I could to get by and support my kids.

But the dream was still very much alive. And after a few years, I met my now wife, Jessica, who encouraged me to go all-in on starting Montana Knife Company.

While I wasn't quite ready to quit my day job, I built some prototypes and took them to an event called WinterStrong in South Carolina. I had the privilege of meeting so many great people at that event, including my future co-founder, Brandon Horoho.

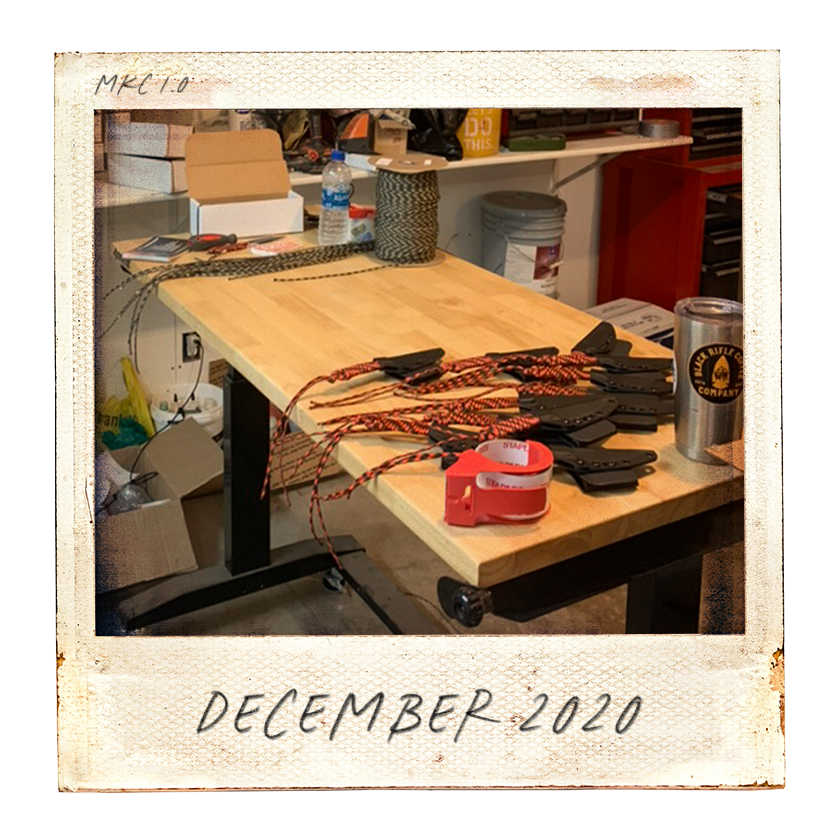

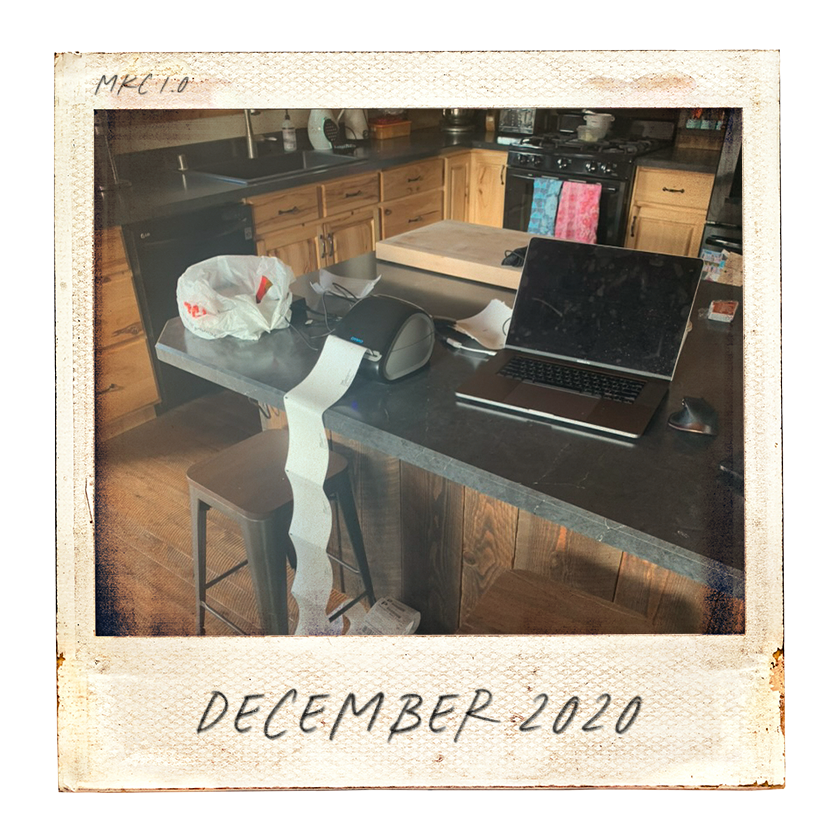

Initially, Brandon helped me create marketing materials and a website for MKC, but he quickly demonstrated just how much more he was capable of. In the fall of 2020, I offered him a partnership in the business, and we officially launched MKC.

Those first knife prototypes sold, and then a few more. I finally quit my job — which, to her credit, my wife had never stopped encouraging me to do — and gave my full time to MKC on December 30, 2020.

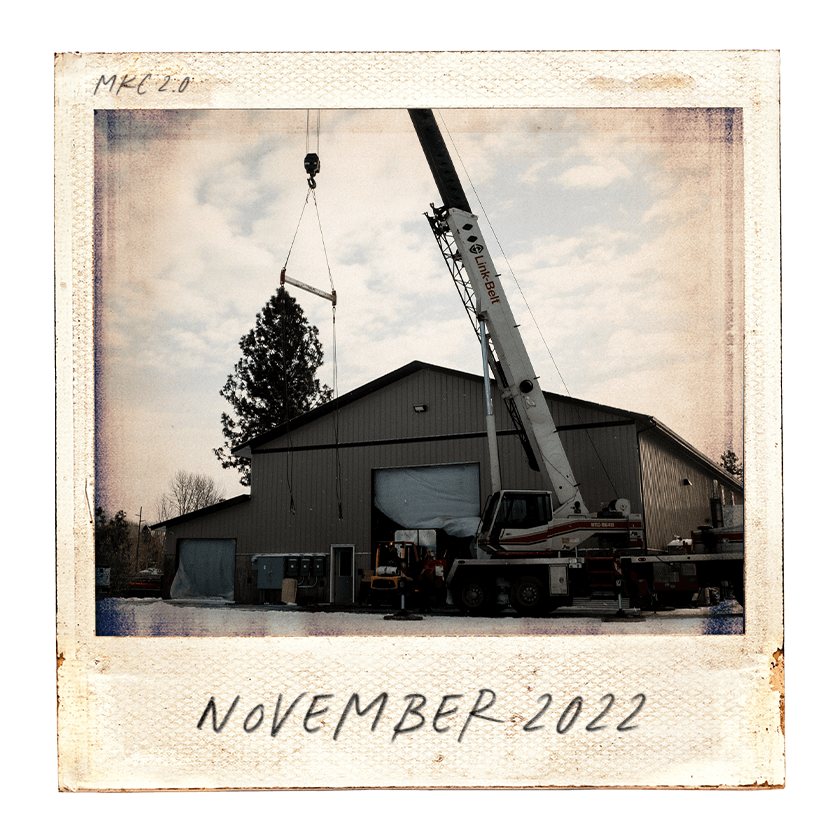

The process was slow at first, but the more knives we made, the more orders we had. When we figured out how to really increase my knife-production capacity, business exploded, and our vision for MKC finally became a solid reality.

MKC 1.0 - The Early Days

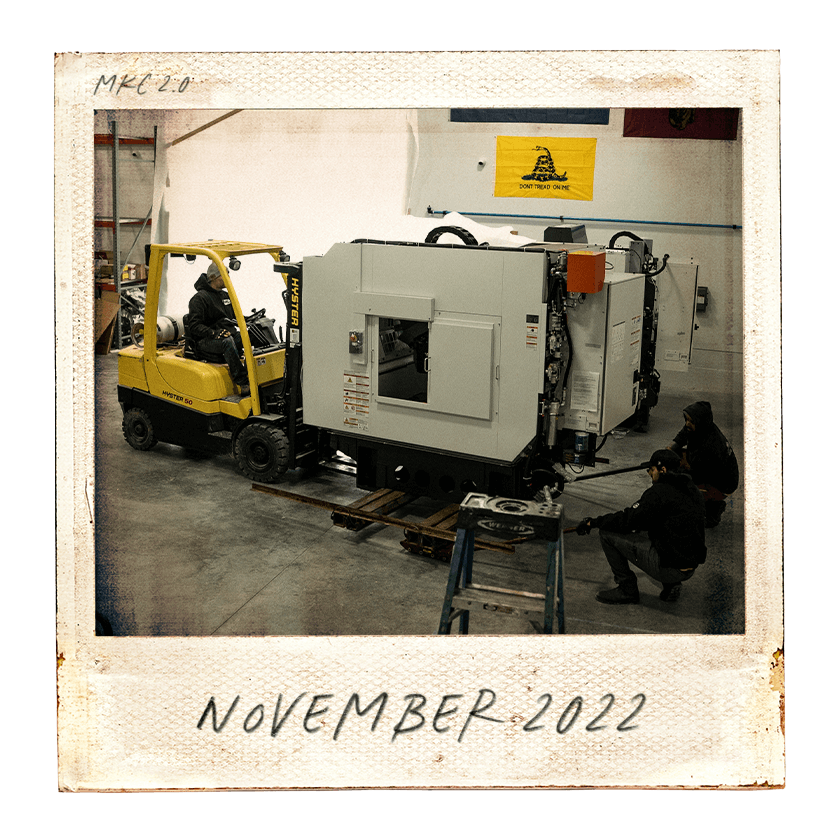

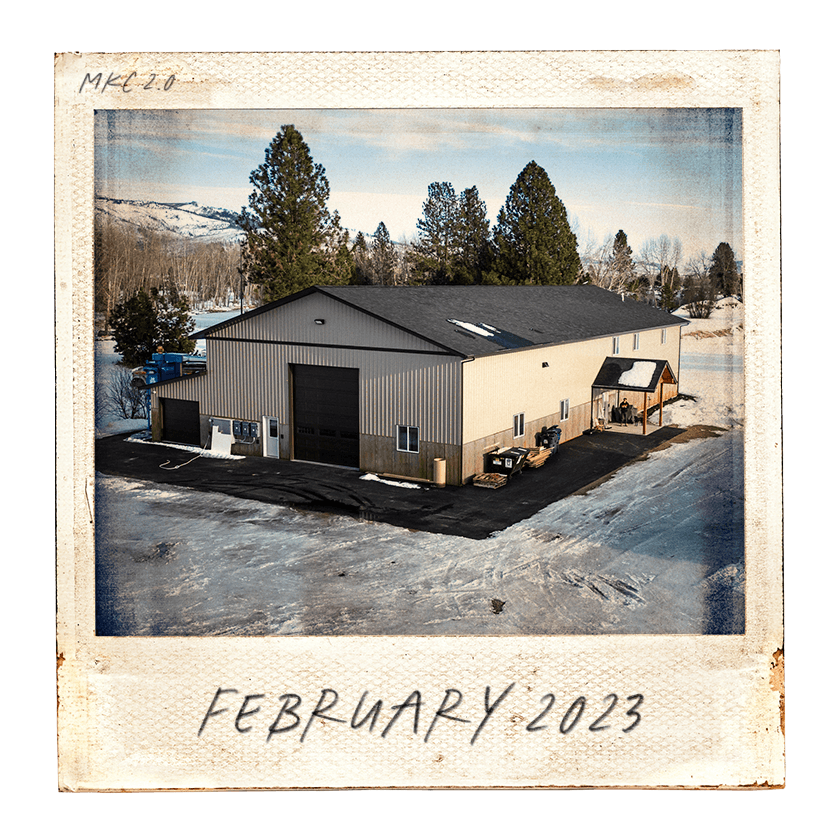

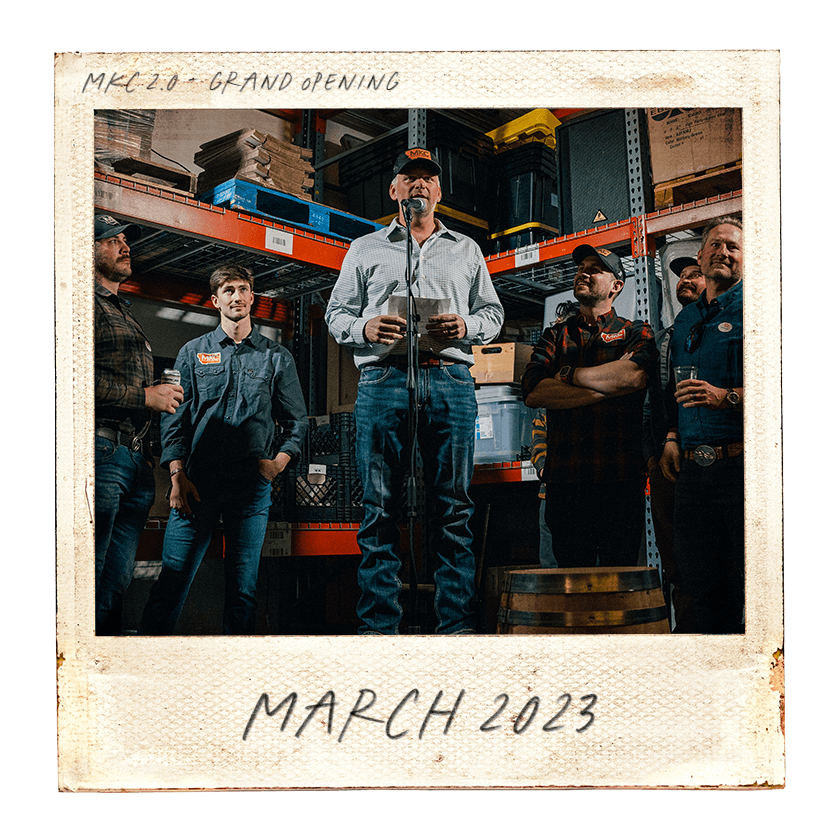

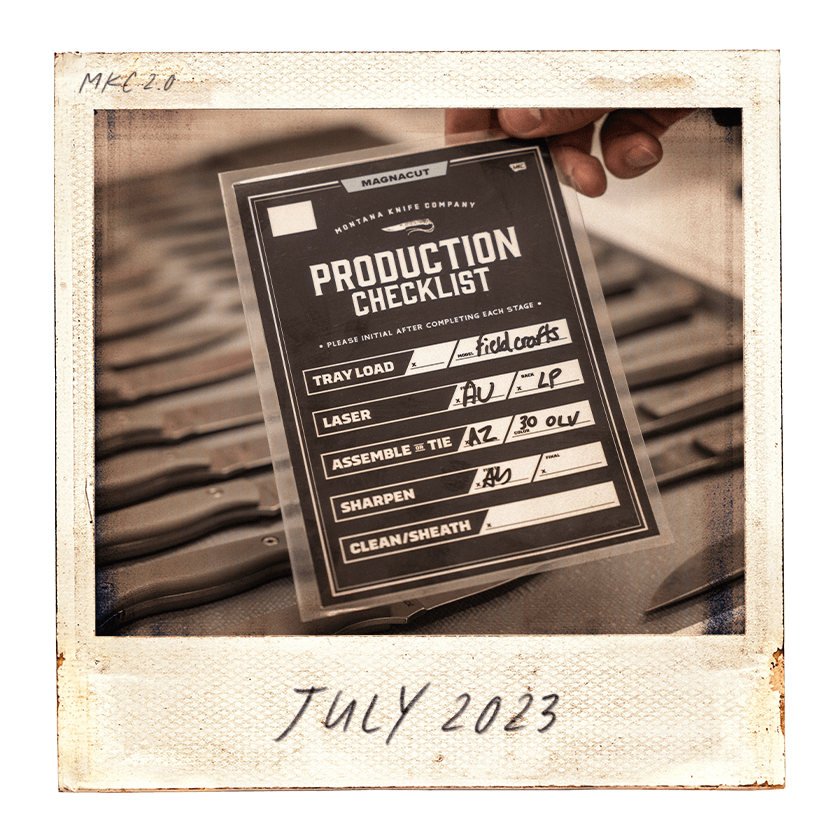

MKC 2.0

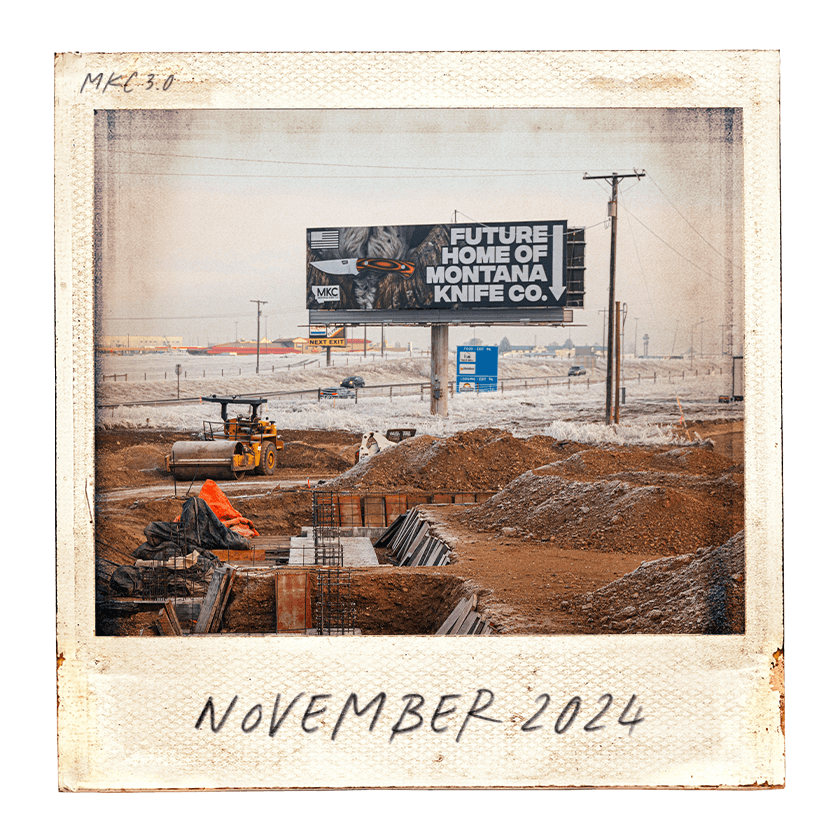

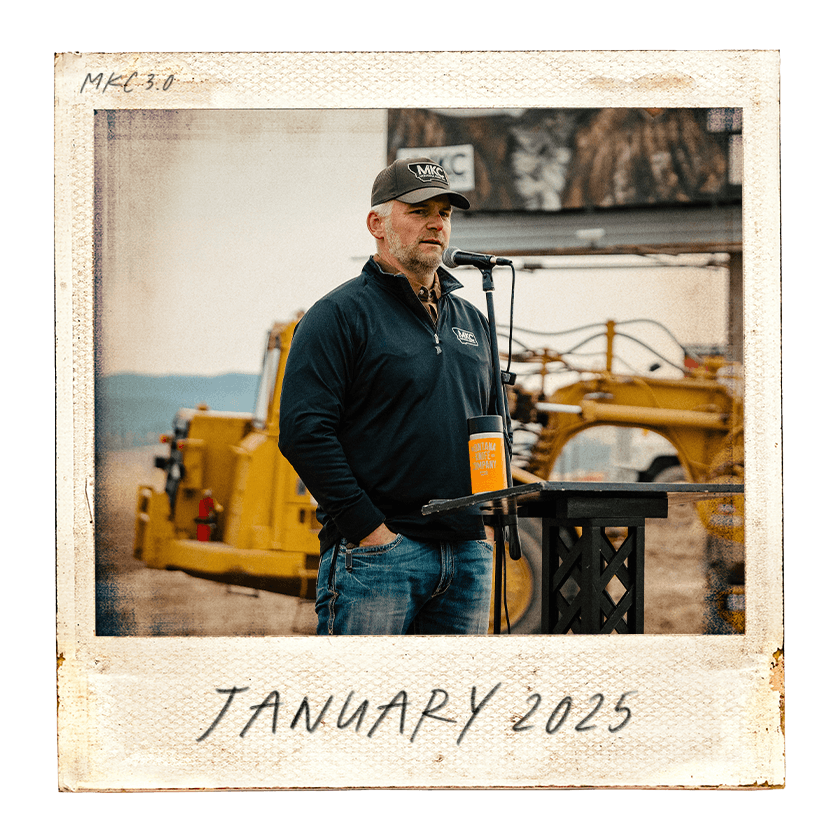

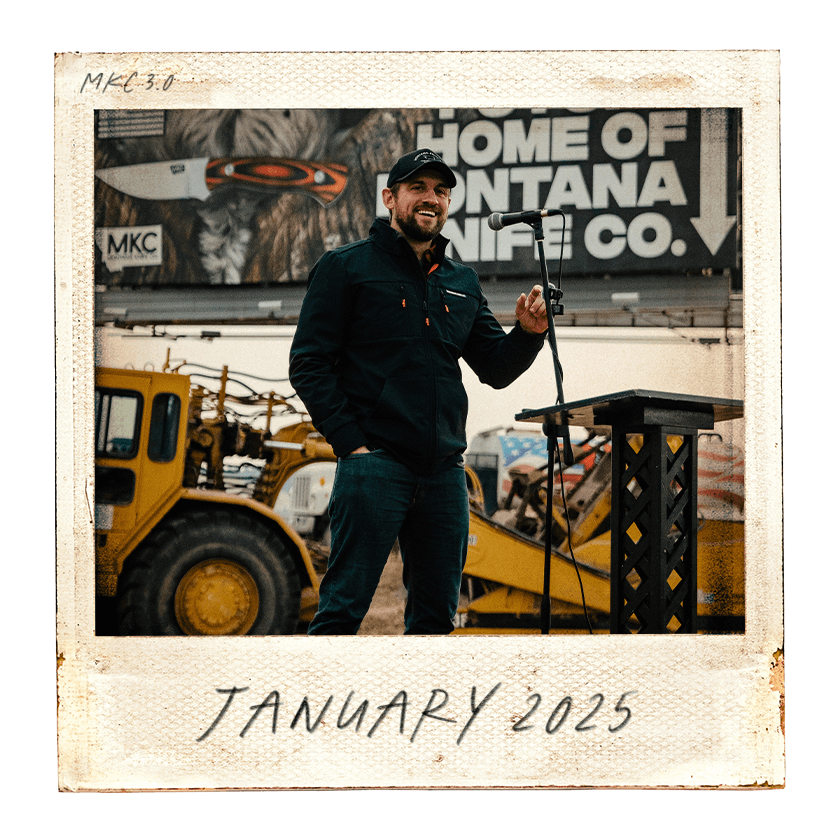

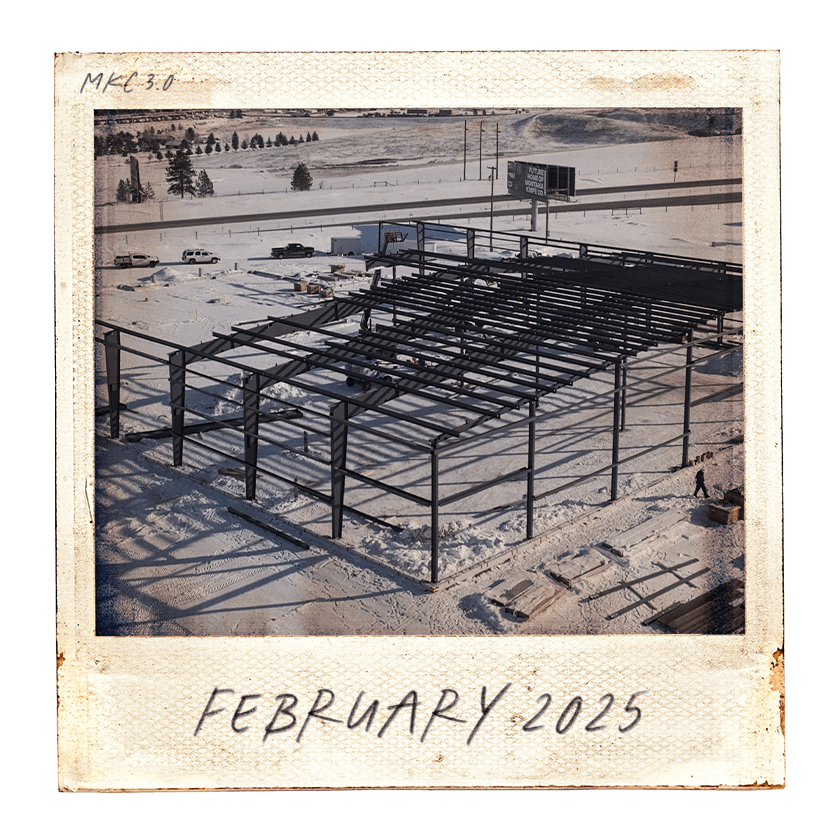

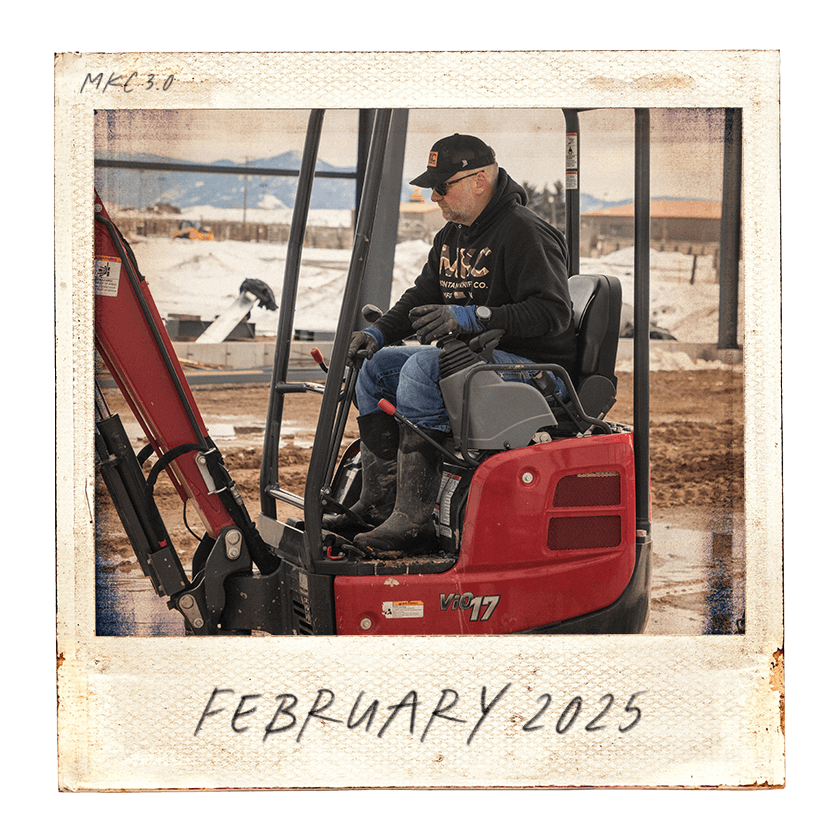

MKC 3.0

2025 and beyond

Looking Forward

The future of American manufacturing isn't competing with overseas factories on price. It's delivering genuine quality and standing behind your work. We're committed to making knives working people can afford and be proud to own, all while keeping manufacturing right here in Montana.

Whether you're a knife owner, a potential team member, or someone who believes in American manufacturing, we invite you to be part of this journey. At MKC, we're building something that matters.