I recently had a question on Instagram about why some knives rust and others don’t. Here’s the answer:

Steel rusts.

Carbon steel. Stainless steel. All steel. It’s a natural process. If you have a knife made out of steel, it can rust.

High carbon knives, of course, have a higher carbon content, as well as little to no chromium, which protects from rust. Stainless steel knives have a higher chromium content, protecting them longer from corrosion but resulting in a less durable blade.

Stainless steel can rust too — it’s a myth that it can’t. It just takes longer. Though with abuse or lack of care, stainless steel can actually rust pretty fast.

Any steel — including stainless — will rust with abuse or lack of care. There are, however, ways to prevent your knife from rusting.

Let’s talk about what rust is, the steps Montana Knife Company takes to keep knives from rusting, and how owners can prevent rust on their knives at home and in the field.

Rust vs. Knife Patina

Rust is the reddish-brown buildup that develops when the iron in steel reacts with oxygen and water. Rust is corrosion, and left unchecked, it will destroy your blade.

Rust is different from a patina. Through exposure to air, moisture, and other substances, the surface of a carbon steel blade can develop a yellowish color — a knife patina. A knife patina can change color over time, even turning brownish black, but this isn’t the same thing as rust.

A knife patina actually protects the surface of a steel blade from rust. And, if you ask me, it adds a lot of great character.

How MKC Keeps Knives From Rusting

At MKC, we build most of our blades out of high carbon steel, but we also take steps to strengthen our blades’ resistance to rust.

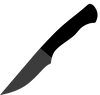

One of those steps is called Parkerizing.

Parkerizing is a process of phosphate coating that protects carbon steel from rust. It originates with the gun industry. Those old, black gun barrels you see are actually made out of carbon steel, but Parkerizing preserved them from rust.

Parkerized steel beats corrosion to the punch. Instead of the surface rusting or even developing a knife patina, the Parkerizing process turns the metal black. Once that happens, it resists rust unless it really gets abused.

Many of our MKC knives have a matte black finish from the Parkerizing process.

Some of our knives, however, have a shinier black or orange finish called Cerakote, which is another way we fight rust.

There are a lot of different coatings out there for rust prevention. We use Cerakote because it’s an incredibly durable, hard, baked-on ceramic finish that’s resistant to wear and tear. Despite this, it’s important to remember that every coating, no matter what it is, can scratch.

Regardless of what kind of advertising or hype you come across, any coating can get scratched — because you use your knife. And that means air and water can get in.

So even if you have a coated blade, you still need to care for it with the rust prevention tips below.

How To Keep Knives From Rusting

Clean the Blade

When you use your knife, make sure you wash it with soapy water and dry it completely before putting it away.

This is especially important if you’re using your knife in the kitchen to cut onions or with vinegar or other acidic materials. These can make steel rust quickly, so it’s crucial to clean them off your blade right away.

Some people do the right thing by washing their blade, but then leave it in the sink. When they pick it up the next day, they find a rough spot where the tip was sitting in a little puddle of water. That’s rust.

No matter what you’re cutting, clean AND dry your blade after each use.

Wax On, Wax Off

Once that blade is clean and dry, apply some MKC blade wax to it. Just wipe it on, and then wipe it off. It’s that easy.

Our MKC blade wax is made with pure, authentic beeswax and Carnauba.

Reapply the wax after each cleaning.

I suggest you use wax even if you have a coated blade. It will keep moisture from getting underneath a scratch in the coating and causing rust.

Even a Parkerized blade can still have vulnerable areas. Anywhere you see silver exposed — like on a logo or sharpened edge — moisture can attack that steel and cause rust. Blade wax will prevent that.

It’s not a bad idea to wax stainless steel blades either.

Some companies claim your knife will never rust if you use their wax. Bull. You’re cutting through hide, flesh, bone, rope, and the like, scrubbing the surface of the knife and removing the wax.

So whatever brand you use, it’s always best to reapply the wax again and again.

Dry Your Sheath

A big thing people can miss for preventing rust on their knives is caring for their sheath. You can clean your blade all you want, but if you throw the knife into a sheath with a bunch of moisture in it — whether that’s saltwater, blood, or anything else — it’s going to cause the blade to rust.

It’s always a good idea to use hot soapy water to clean the sheath.

Then make sure the sheath is dry to keep your knife from rusting inside.

The Best Oil To Keep Knives From Rusting

There are a lot of different waxes and oils you can use to keep knives from rusting, including gun oils.

One problem I have with oils is that some of them actually attract moisture, even humidity from the air. So if the oil isn’t covering the entire blade, it can actually counteract the intended corrosion resistance and promote rust.

Another problem with oils — gun oils, WD 40, or any other kind — is that they’re not food safe.

If you decide you want to carve up an apple out in the field with your hunting knife, you’re going to get an oily taste on your snack. It’s not going to kill you, but it’s not great for you either. Plus, it ruins the taste of your food.

A lot of oils also have a strong odor. And if you can smell it, animals can smell it better. When you’re out hunting, smelly oils can alert game to your presence from a long way off, especially in the wrong wind.

This is why we developed MKC blade wax the way we did. It’s made with natural materials like beeswax, it’s food safe, and it doesn’t stink. You can also use it on your leather boots, leather gun slings, horse bridles, or whatever you want. It even works on your cutting board.

You can carry it with you wherever you go.

Watch Out for Saltwater

One last thing to consider when you’re thinking about coatings, rust, and caring for knives is what conditions you’re exposing your knife to.

Of all the conditions your knife is exposed to, saltwater is the harshest.

For this reason, I don’t suggest using carbon steel knives in a saltwater application. It’s a big reason why we started implementing our MagnaCut stainless steel.

If you’re fishing, diving, or working near the ocean, take a MagnaCut stainless-steel blade with you. Carbon steel, no matter what you do, is going to be tough to keep in good shape around saltwater.

That being said, even stainless-steel blades need to be kept clean and dry to prevent rust. And don’t forget to coat them with MKC blade wax.

by Josh Smith, Master Bladesmith and Founder of Montana Knife Company